Products

Shaped Refractory

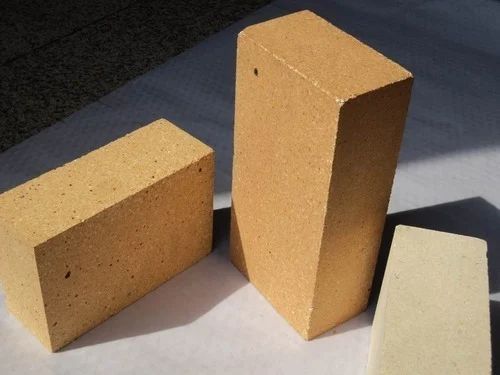

Alumina Silicate Bricks

We manufacture a wide range of Alumina-Silicate Bricks with alumina content ranging from 25% to 85%. We provide top-quality bricks tailored to your needs, all at highly competitive prices.

Cordierite Bricks

specialized type of Alumina-Silicate brick, are designed to contain the Cordierite phase. Known for their excellent thermal shock resistance, we manufacture it with alumina content ranging from 35% to 45%, with thermal shocks that surpasses 90 cycles.

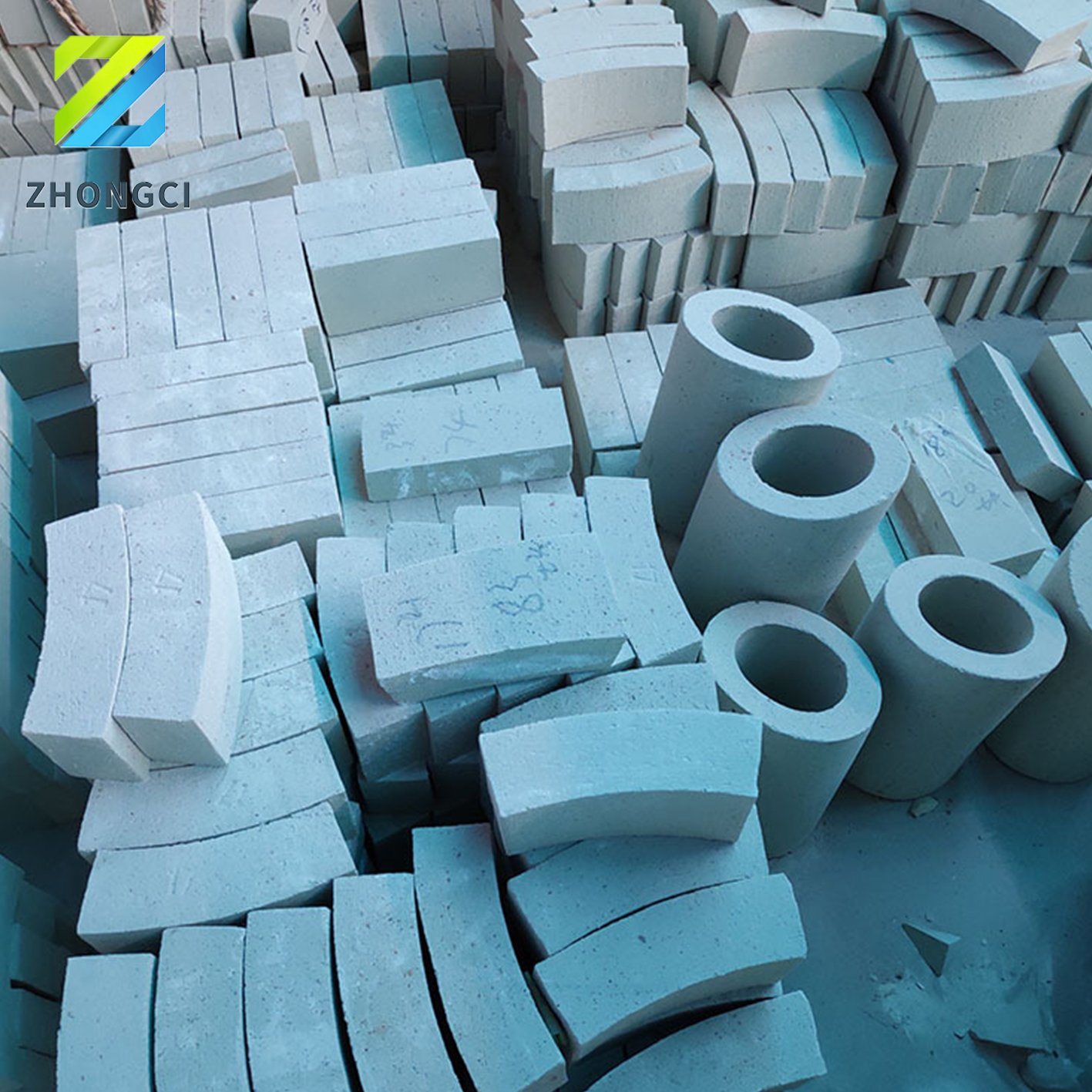

Light Weight Bricks

Light weight bricks are high-quality, insulating refractory products designed to reduce structural weight while providing excellent thermal insulation. These bricks, containing alumina content that ranges from 35% to 80%, are ideal for high-temperature applications such as kilns, furnaces, and other thermal processing equipment. Their high porosity ensures efficient heat retention, energy savings, and reduced overall structural load, enhancing the performance and longevity of industrial installations.

Anti Acid Bricks

Anti acid bricks are specialized refractory products designed to withstand acidic and alkaline environments. Nourmetec produces these bricks with an alumina content ranging from 35% to 80%, providing excellent chemical resistance, mechanical strength, and thermal stability

Unshaped Refractory or Monolithic Refractory

Magnesia Monolithic

Magnesia monolithics are a type of unshaped refractory material that primarily consists of magnesia content. They are known for their excellent resistance to basic slags, high-temperature stability, and mechanical strength.

Ramming

These materials, with magnesia content ranging from 75% to 93%, are installed by ramming them into place, creating a dense and durable lining. They are used for lining induction furnaces, tundishes, and other high-temperature equipment.

Hot Gunning

These gunning mixes, containing 85% to 93% magnesia, are sprayed onto surfaces using gunning equipment, providing a quick and effective way to create a refractory lining. They offer good adhesion and high-temperature performance.

Spraying

Magnesia spraying materials, with magnesia content ranging from 70% to 80%, are applied through spraying techniques to form a refractory lining, offering quick installation and excellent coverage.

Fettling

These fettling materials, containing 80% to 90% magnesia, are used for repairing and maintaining refractory linings in furnaces and other high-temperature equipment, ensuring prolonged service life.

Backfilling

Magnesia backfilling materials, with magnesia content ranging from 70% to 75%, are used to fill gaps and voids in refractory linings, providing structural support and enhancing overall integrity.

Silica Ramming Mass

Silica ramming mass is a high-quality, unshaped refractory material composed primarily of silica. It is designed for lining induction furnaces and other high-temperature applications, offering excellent thermal stability, high density, and superior corrosion resistance.

Magnesia Mortar

Magnesia mortar is a high-performance bonding agent used for joining magnesia bricks and other refractory components. Composed of more than 98% magnesia and 0.1% iron oxide, this mortar provides excellent mechanical strength, thermal stability, and resistance to basic slags and high temperatures (up to 1750 degrees). It ensures a tight and durable bond, enhancing the structural integrity and longevity of refractory linings in furnaces, kilns, and other high-temperature industrial applications.

Alumina Silicate Castable

Alumina-silicate castables are unshaped refractory products designed to replace bricks in certain applications, allowing them to be cast and shaped on-site. Nourmetec is the only company in the Middle East capable of producing a wide variety of alumina-silicate castable types, ensuring versatility and superior performance for diverse industrial needs. These types include:

- Traditional Castable

- Low Cement Castable

- Ultra Low Cement Castable

- No Cement Castable

- Spinel Castable

- Gunning Castable

- Free Flow Castable

Special Castable

Special castables are engineered to meet the demands of specific high-temperature applications. Nourmetec offers the flexibility to manufacture these castables with an alumina content ranging from 80% to 95%. This customization ensures excellent performance, durability, and suitability for diverse industrial requirements.

Conventional Castable

Conventional castables are designed for applications in high-temperature environments, they provide excellent mechanical strength and durability. Nourmetec offers this type of castable for a wide range of applications, with an alumina content ranging from 40% to 95% and a silicon dioxide range that can reach 0.2%.

Light Weight Castable

Lightweight castables are designed for applications in high-temperature environments, such as kilns and furnaces. They provide efficient heat retention while reducing overall structural weight. Nourmetec offers this type of castable with an alumina content ranging from 30% to 90%.

Industrial Minerals

Calcined Kaolin

Calcined kaolin is a highly refined industrial mineral obtained by heating natural kaolin clay in rotary kilns, a process that removes moisture and organic matter while enhancing the material’s brightness, hardness, and chemical resistance. Nourmetec’s calcined kaolin can contain up to 42% alumina, 54% silica, and a range of 0.9% to 1.2% of iron dioxide with trace amounts of other elements. Applications of calcined kaolin include ceramics, paper, paints and coatings, rubber and plastics, catalysts, adhesives and sealants, and cosmetics, where it enhances performance and provides superior quality.

Calcined Dolomite

Calcined dolomite is a high-quality industrial mineral produced by heating dolomite in rotary kilns, which removes carbon dioxide and enhances its chemical and physical properties. Typically, calcined dolomite contains around 50% to 60% calcium oxide (CaO) and 30% to 35% magnesium oxide (MgO). It is widely used in applications such as steelmaking, fertilizers, and environmental protection due to its excellent reactivity, high purity, and thermal stability. Applications of calcined dolomite include enhancing the performance and efficiency of steelmaking processes, serving as a soil conditioner and magnesium source in fertilizers, and aiding in environmental protection efforts by neutralizing acidic environments and treating wastewater.

Calcined Lime (Calcium Oxide)

Calcined lime, also known as quicklime, is produced by heating limestone in rotary kilns, which removes carbon dioxide and enhances its chemical and physical properties. Nourmetec’s calcined lime contains a range of 80% to 94% calcium oxide (CaO). It is widely used in applications such as steelmaking, construction, chemical production, agriculture, paper & pulp industry, mining and environmental protection due to its high reactivity, purity, and thermal stability. Its unique properties make it an ideal choice for various industrial applications, ensuring optimal performance and durability.

Hydrated Lime (Calcium Hydroxide)

Hydrated lime, also known as calcium hydroxide or slacked lime, is produced by adding water to quicklime. This process results in a fine, dry powder that is highly reactive. Nourmetec’s hydrated lime contains around 85% to 95% calcium hydroxide, and is widely used in applications such as water treatment, environmental protection, construction, soil stabilization, flue gas treatment, food industry, paper & pulp industry and chemical production due to its excellent reactivity, purity, and versatility. Its unique properties make it an essential material for various industrial processes, ensuring optimal performance and efficiency.

Fluorspar (Calcium Fluoride)

Fluorspar, is a high-quality industrial mineral composed primarily of calcium fluoride. Nourmetec’s Fluorspar is available in different grades, with purity levels ranging from 45% to 87% calcium fluoride. It is widely used in applications such as steelmaking, cement, aluminum production, glass manufacturing, dentistry and the chemical industry due to its excellent properties, including low melting point, high thermal stability, and chemical resistance. Fluorspar enhances the performance and efficiency of various industrial processes, ensuring optimal results and durability.

Calcium Carbonate

Calcium carbonate is a versatile industrial mineral composed primarily of calcium carbonate content. Available in Nourmetec in various grades and grain sizes, it contains over 98% calcium carbonate. It is widely used in applications such as construction, pharmaceuticals, food production, and the paper and plastics industries due to its excellent properties, including high purity, chemical stability, and whiteness.

Carbon Black

Our carbon black is a high-quality, fine black powder with a high carbon content. Produced sustainably by recycling tires through incomplete combustion, it serves various applications, including rubber reinforcement, pigments for inks and coatings, plastics, and batteries.

Decoration Bricks

The decorative bricks manufactured by Nourmetec are available in a wide range of colors, including yellow, light orange, dark brown, light red, dark red, light grey, dark grey, and black. These bricks are characterized by their high-quality refractory properties, ensuring durability and resistance to high temperatures.

Each brick is precision-crafted to maintain consistent size, shape, and color, suitable for various architectural and construction applications. The diverse color palette allows for creative design possibilities in both interior and exterior projects. Our decorative bricks meet stringent regulatory standards and are designed to integrate seamlessly with other building materials, providing both aesthetic appeal and structural integrity.